When you think of Transformers, the movie, your mind might instantly race to Optimus Prime —the iconic semi-truck leader from the movie franchise. Like this fictional hero charged into battles with its futuristic technology, today’s real-world trucks and semi-trucks are embarrassing artificial intelligence. From reshaping the logistics to optimizing fleet management, artificial intelligence in the trucking industry is entering a new era of efficiency, safety, and innovation.

While we love a good hi-tech fighting sequel, AI is helping shape the global supply chain by integrating new systems, tools, and software. Through smart technology solutions, trucking companies are now addressing key challenges like peak seasons, fuel consumption, route planning, and driver safety easily.

Let’s explore more about how AI trucking in transformation is evolving and its impact on carriers and brokers.

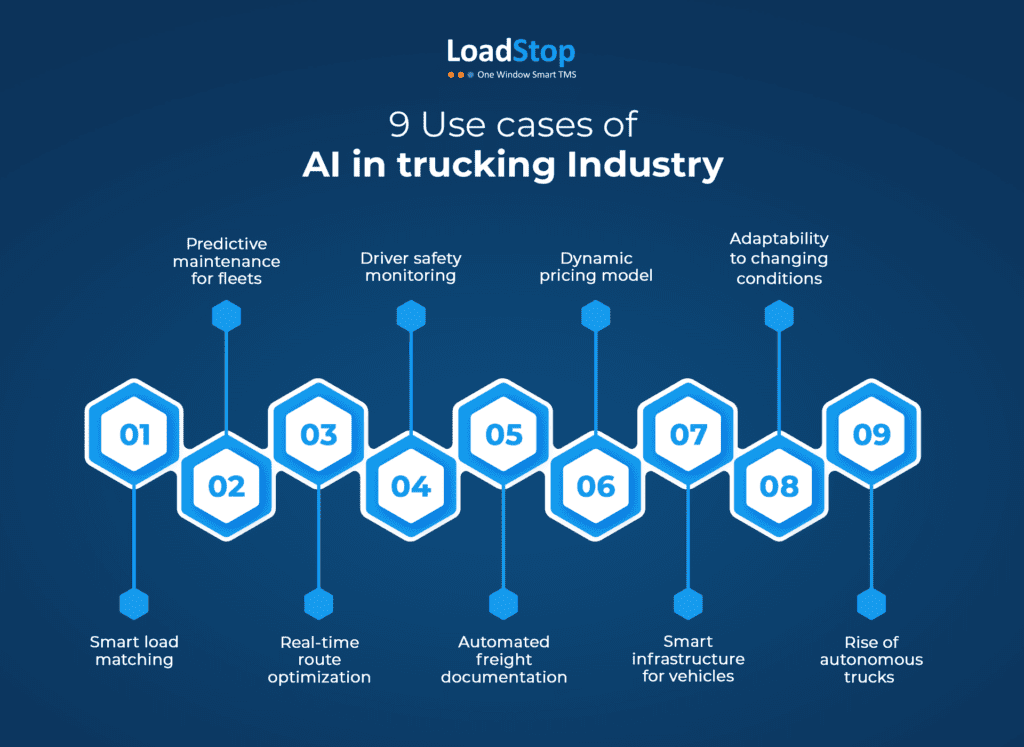

9 Use cases of AI in trucking Industry

Artificial intelligence in transportation is navigating through AI’s capabilities to enhance trucking operations, improve safety, optimize costs, and do a lot more to ensure fleets are smarter and more efficient.

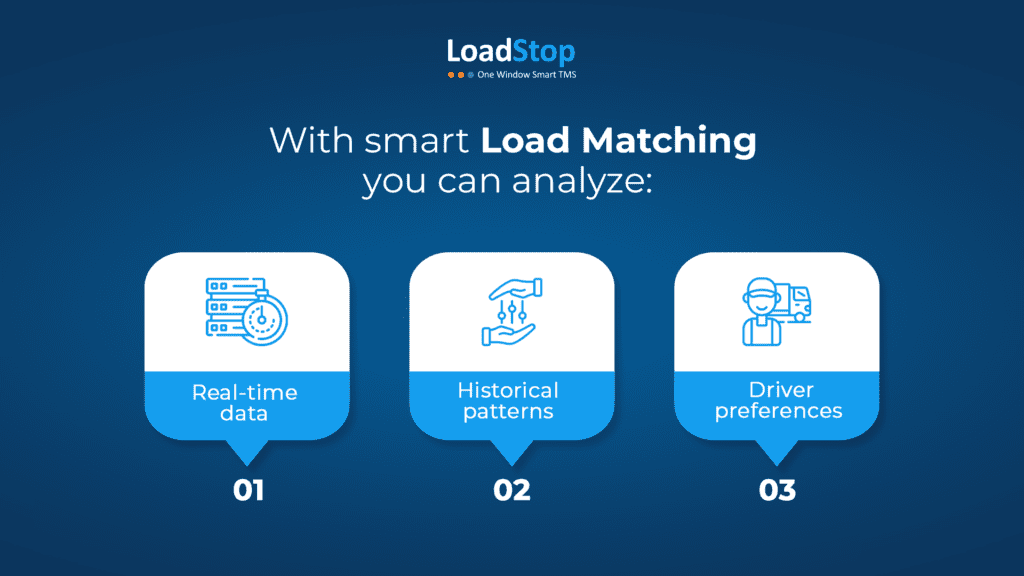

Smart load matching with AI algorithms

One of the smartest technologies is the AI-powered smart load-matching system. The tools make carriers’ and broker’s lives easier thanks to the advanced algorithms to match the right freight with the right carrier, optimizing routes, costs, and delivery timelines. You can easily analyze real-time data, historical patterns, and driver preferences.

These systems increase carriers’ efficiency and profitability by enabling them to prioritize high-value or time-sensitive freight and allocate loads more quickly—in minutes as opposed to hours. Smart load matching is anticipated to incorporate elements like automated bidding and forecast freight demand as technology advances, securing its position as a key component of contemporary transportation logistics.

Predictive maintenance for fleet efficiency

By streamlining vehicle maintenance schedules, AI-driven predictive maintenance is revolutionizing fleet management. Artificial intelligence (AI) systems use sensors and data analytics to continuously monitor important metrics including tire condition, engine performance, and fluid levels.

AI systems can anticipate possible maintenance problems before they develop into significant malfunctions by examining past data and looking for trends. By scheduling maintenance and repairs at suitable times, this proactive approach helps businesses reduce downtime and increase fleet availability. Predictive maintenance lowers overall maintenance costs by extending vehicle lifespan and improving operational efficiency.

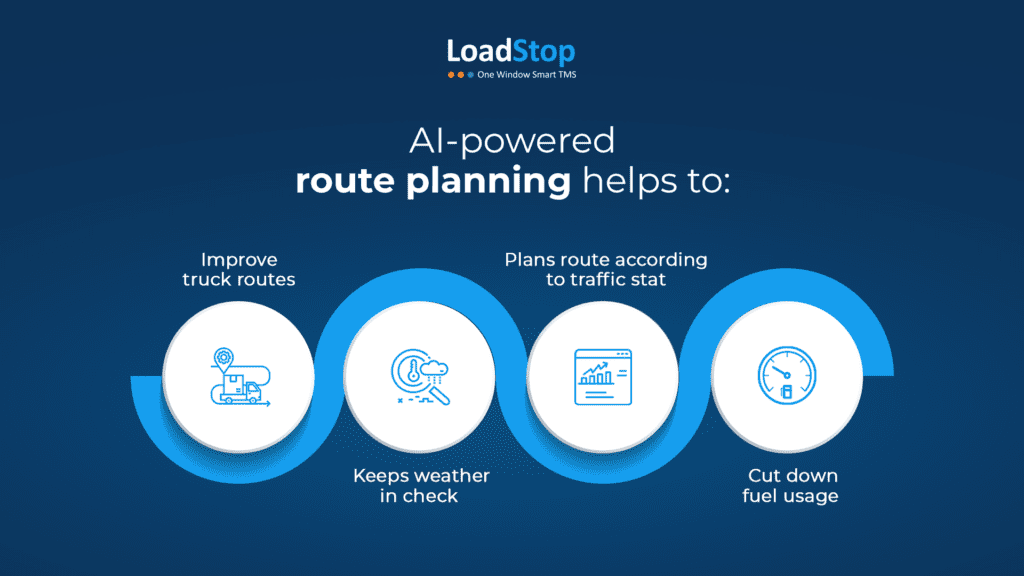

Real-time route optimization

To improve truck routes, AI-powered route planning algorithms take into account weather, traffic statistics, and other factors in real time. AI algorithms can determine the most effective routes, cutting down on travel time and fuel usage, by evaluating both historical and current data.

Because of their ability to adjust to changing circumstances, these intelligent systems can give drivers real-time updates and other routes to escape traffic jams or road closures. By guaranteeing on-time delivery, intelligent route planning and optimization increase customer happiness in addition to efficiency.

Enhanced driver safety monitoring

We believe that in the short run, research on autonomous vehicles will have more immediate and significant benefits for human drivers’ safety. Even if autonomous trucks don’t become available in the next decade, the technology that enables their advanced capabilities is already being refined to enhance the safety and productivity of human drivers on the road.

We are confident that various autonomous control systems, including lane-keeping, lane-changing assistance, merging assistance, lidar, radar, camera systems, adaptive/predictive cruise control, and electric steering systems, will become commonplace, if not mandatory, features in trucks and passenger cars shortly.

These technologies are designed to directly aid human drivers. As these systems become more widely adopted, we expect the trucking industry to make significant investments in them to safeguard drivers, the general public, and their profits.

Automated freight documentation

Administrative work can be laborious and prone to mistakes. AI is used by advanced TMS as an automated freight documentation capability to track shipments, create invoices, and handle compliance documentation. Fleet managers can concentrate on strategic priorities as a result of the automation’s reduction of manual errors and acceleration of the billing cycle.

There are many advantages to using AI in freight documentation. For example, Expedock, an AI-powered automation supplier, calculates that CargoWise freight forwarders who haven’t used automation are losing out on labor savings of 40% to 80%.

AI-powered document processing can also result in better service quality and quicker deliveries. According to a case study by WNS, using AI and ML to automate freight document processing reduced average handling time and improved accuracy.

Dynamic pricing model

AI is used by the dynamic pricing function to evaluate demand variations, market conditions, and historical data in order to provide the best pricing plans. This helps carriers, particularly in erratic freight markets, to maintain their competitiveness while optimizing profitability.

Revenue can be greatly impacted by AI-driven dynamic pricing schemes. For instance, it is anticipated that the use of AI in trucking will result in a 30% reduction in delivery time, improving operational effectiveness and customer satisfaction.

AI can also help truckers save up to 20% on maintenance expenses, which increases profitability.

Smart infrastructure for vehicles

The concept of “Smart” Infrastructure is being explored by developers of autonomous vehicle systems, which essentially enable trucks to operate independently while on the road. The technology primarily relies on data from radar, lidar sensors, and camera systems to gather information about the operating environment.

However, the absence of outside information from other vehicles on the road and structures along the route such as “smart” guide rails, lane markers, traffic lights, or road signs creates a potential hurdle for the safe deployment of autonomous vehicles.

Therefore, it is plausible that society might delay the deployment of autonomous vehicles until a network of connected vehicles and smart road infrastructure is in place to facilitate safe operations.

Adaptability to changing conditions

The capacity of AI-powered systems to adjust to shifting road conditions is one of their main benefits. AI-powered route optimization software, for example, can dynamically modify routes in reaction to accidents, traffic jams, or road closures, guaranteeing that deliveries continue on time even in the face of unanticipated delays.

In a similar vein, self-driving vehicles that are outfitted with artificial intelligence algorithms can effortlessly maneuver through intricate traffic scenarios, constantly refining their routes to prevent delays and gridlock. In the fast-paced transportation environment of today, when even small disruptions can have a big impact on supply chain operations, this flexibility is essential.

Rise of Autonomous Trucks

The progress made in the AI-powered trucking industry has led to a remarkable breakthrough – the development of autonomous trucks. These self-driving vehicles hold immense potential to revolutionize transportation by mitigating driver fatigue, enhancing fuel efficiency, and elevating road safety.

Prominent companies such as Tesla, Waymo, and Daimler are investing substantial resources into autonomous truck technology, with certain models already undergoing rigorous testing. As these advancements continue, we can anticipate a future where driverless trucks become a more prevalent on our roadways.

An autonomous future will transform the trucking industry

Shortly, we will witness a careful and limited implementation of Level 4 and Level 5 autonomous trucks in the American Southwest. Additionally, we may observe a high adoption rate of autonomous safety systems to assist human drivers in areas where human drivers are still required.

In any case, we are certain that the trucking industry will eventually shift towards autonomous technology. The only uncertainties are when this transition will occur and to what extent it will be adopted. Using a cloud-based TMS system will help you stand out from the competition, so using LoadStop is the best software in the trucking industry. It will help you streamline operations, manage fleets, integrate other systems, prepare AI invoicing, and automate fleet planning in just a few clicks.

Got fleets? Reduce 5x deadhead miles!

Try LoadStopFAQs

In the United States, for example, several companies are testing autonomous trucks in certain regions and on specific routes. The adoption of truck driving automation is expected to be gradual, with autonomous driving technology being integrated into existing trucking operations rather than replacing human drivers entirely.

Driving a truck demands decision-making, problem-solving, and the capacity to react to unforeseen circumstances in addition to the physical task of directing the vehicle. Despite the rapid advancement of AI, machines are still unable to match the adaptability and flexibility of the human mind.

AI-powered smart load matching optimizes freight assignments, reduces empty miles, and cuts costs. It uses real-time data to streamline routes, prioritize shipments, and match loads efficiently, boosting revenue, fleet utilization, and driver satisfaction while lowering fuel consumption and emissions.